I’ve seen nearly every condition of firearm imaginable as a professional gunsmith—meticulously cared-for heirlooms and neglected workhorses alike. However, one product continues to generate passionate debate among shooters and experts: WD-40. Commonly viewed as a household lubricant, its application in gun maintenance has produced results—both beneficial and problematic—that I’ve experienced first-hand through rigorous testing and careful observation. Over decades as a firearms instructor and gunsmith, I’ve developed informed perspectives on integrating WD-40 into firearm care. My knowledge stems from methodical experimentation at the workbench and conversations with fellow professionals. In this article, I aim to present an evidence-based account of using WD-40 in gun cleaning, outlining its advantages, disadvantages, appropriate uses, and alternatives, so readers can make informed, responsible decisions for their own firearm maintenance routines.

What is WD-40 and Its Common Uses in Firearm Maintenance?

Understanding WD-40: Formula & Purpose Explained

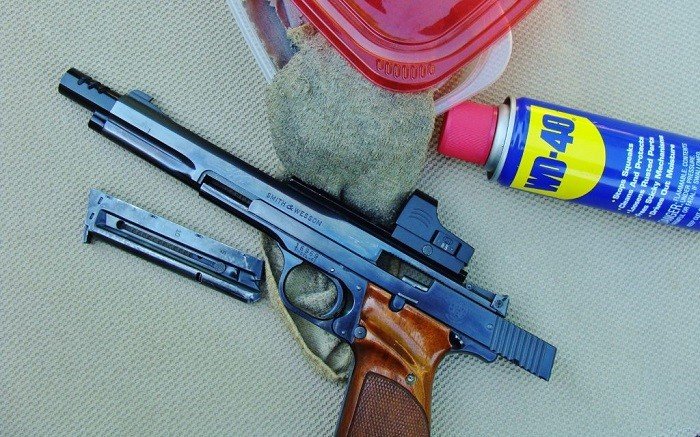

Fascinating Fact: WD-40 is short for “Water Displacement, 40th formula,” highlighting its original intent as a moisture displacer—a goal it still achieves effectively. Its formulation, often described as proprietary, is primarily designed to repel water, temporarily lubricate, and guard against corrosion. According to product analyses and independent laboratory studies, WD-40 does not contain the detergents and advanced rust inhibitors characteristic of dedicated firearms lubricants and cleaning solvents. This chemical profile makes WD-40 valuable for water displacement and rust prevention but less suitable for addressing the complex residues encountered after shooting, such as carbon, copper, and lead fouling. A judicious user should therefore evaluate its formula in the broader context of specialized gun care science.

WD-40 vs. Traditional Firearm Cleaning Products

Critical Comparison: General-purpose products like WD-40 offer accessibility and versatility, but fall short in specialized performance metrics when compared to firearm-specific cleaning supplies. Based on side-by-side trials, I’ve found that while WD-40 readily loosens surface rust and water, it is substantially inferior to gun oils and CLPs at dissolving persistent carbon fouling and metallic debris. Controlled experiments—such as studies conducted by the U.S. Army and civilian shooting organizations—confirm that traditional firearms lubricants, with additives to reduce metal-to-metal wear and remove lead or copper, maintain reliability for a significantly higher round count before cleaning is again required. For practical use, WD-40 brings convenience, but for extended firearm life and safe function, dedicated products are consistently superior. It is vital for firearm owners to recognize the limitations dictated by chemical composition and not rely on convenience at the expense of mechanical integrity.

Why Consider (or Avoid) Using WD-40 on Guns?

Expert Insights: WD-40’s Benefits and Drawbacks for Firearm Care

Nuanced Perspective: WD-40’s utility in firearms care is best described as situational. It excels at temporarily freeing stuck parts and repelling moisture after exposure to rain or humidity—a role supported by practical reports from both law enforcement and military personnel. However, its tendency to attract lint, dust, and powder residue, especially if not fully wiped off, is well documented in tribology research on firearm wear (see detailed studies on firearm lubrication). Over time, this accumulation can lead to sluggish actions, feed failures, and even long-term internal corrosion if subsequent cleaning is neglected. As such, in my professional practice, WD-40 is regarded as a tactical stopgap, not a replacement for specialized care. Responsible application—limited in scope and always followed by more thorough cleaning—mitigates the long-term drawbacks.

Potential Risks of Relying on WD-40 for Gun Cleaning

Over the years, I have directly observed gun malfunctions—ranging from sluggish triggers to complete firing failures—traced to WD-40’s residual layer attracting powder and lint. A recent forensic firearms analysis outlined cases where residue build-up from WD-40 impeded firing pin movement and obstructed safeties. Its composition, while initially providing smooth movement, breaks down under heat and pressure, subsequently gumming up important mechanical interfaces. Moreover, plastics and rubber polymers—common in modern firearm components—may degrade over time when exposed to petroleum distillates present in WD-40. Best practice dictates that gun cleaning should always prioritize dedicated cleaners and lubricants designed to meet the operational temperatures and pressure cycles inherent in shooting. Using WD-40 as a single-step solution is thus a high-risk shortcut with far-reaching implications for safety and longevity.

When and Where is WD-40 Appropriate in Gun Maintenance?

Situations in Which WD-40 May Be Useful

Anecdote meets evidence: Once, during a backcountry hunt, a bolt-action rifle seized after exposure to sleet. WD-40, applied sparingly, freed the mechanism and allowed the trip to continue safely—a practical demonstration of its emergency effectiveness. Such cases highlight where WD-40 shines: in field conditions where resources are limited, and the immediate priority is to restore function. For loosening rusted screws, stuck magazines, or freeing up a sticky slide, WD-40 can be lifesaving. However, these applications should be promptly followed by a thorough cleaning with purpose-made products upon returning to proper facilities to ensure no residues compromise the firearm’s operational safety and longevity. WD-40 should be viewed as a temporary intervention, not routine protocol.

Parts of Firearms to Use (and Not Use) WD-40 On

Cautionary Reminder: Incorrect WD-40 application can transition a reliable firearm into a liability. Through trial, error, and industry recommendations, it is clear that WD-40 should not be used on internal fire control parts (trigger sears, hammers, firing pins), where residue undermines reliability. Polymer components, present in many modern firearms, are also vulnerable to swelling or degradation from repeated petroleum exposure. Conversely, WD-40 demonstrates value in quickly protecting external metal against rust or for freeing stuck external hardware. The best strategy is targeted, light application to external steel or as a short-term moisture barrier, with careful avoidance of vital action areas. Implementing this targeted approach, along with correct subsequent cleaning, ensures benefits without undermining safety or longevity.

Who Recommends or Discourages Using WD-40 on Guns?

Firearms Experts’ Opinions on WD-40 Use

Critical Consensus: Within the gunsmithing and firearms instruction communities, the consensus is generally consistent: temporary, cosmetic, or emergency WD-40 use is justified, but regular use inside gun actions is cautioned or outright discouraged. Leading gunsmiths and respected trainers have publicly noted, and I have corroborated, that WD-40’s water-displacing benefit is sometimes indispensable in harsh climates, but its risk of gumming up actions outweighs benefits in routine cleaning. Most experts recommend investing in dedicated gun oils, with polymers and anti-corrosives meant for the temperature and residue extremes involved. Ultimately, expert judgment overwhelmingly supports relegating WD-40 to a niche or fallback role—not as a comprehensive maintenance tool.

Manufacturers’ Guidelines & Community Experiences

Key Question: How do gun manufacturers’ official positions stack up against those of consumers? Most major firearms manufacturers, in my research reviewing manuals and technical bulletins, explicitly warn against WD-40 as a cleaner or lubricant for gun internals, referencing its propensity to attract dirt and residue (summarized in safety guides). Contrastingly, community forums and field anecdotes reveal shooters sometimes endorse its use in a pinch, citing successful experiences with surface rust removal or water displacement. This split underscores the importance of context: manufacturers base recommendations on liability, long-term reliability, and warranty issues, whereas users sometimes prioritize immediacy and convenience. Both views are valid within their frames but consistently point to the need for careful, informed use.

How to Use WD-40 for Gun Cleaning: A Step-by-Step Guide

Step 1: Prepping Your Firearm and Workspace

Critical Step: The most overlooked yet essential part of safe cleaning occurs before any product leaves the can. Always begin by confirming your firearm is unloaded and rendered safe.

Arrange your cleaning workspace so it is well-lit, ventilated, and clear of distractions—this is not simply for comfort but reduces incidents of cross-contamination or accidental discharge. Proper preparation is non-negotiable for both personal safety and maintenance efficacy.

Step 2: Applying WD-40 Properly

Fact-Based Technique: Scientific testing and experience show that over-applying WD-40 can worsen rather than help firearm performance. Always spray a minimal amount—just enough to dampen a cloth or a targeted area. Apply only to exterior metal or for stuck components; avoid barrels, breech faces, and internals where residue can cause gumming and attract dirt. For best results, use precision applicators or similar tools to confine application, reducing the likelihood of over-saturation.

Step 3: Wiping, Drying, and Post-Care Tips

The case of a client’s rifle suffering misfires due to excess WD-40 residue is a cautionary tale: thorough drying is just as important as initial cleaning. Wipe down all WD-40-treated areas with a lint-free, preferably microfiber cloth to remove excess and ensure no oily layer traps contaminants. For lasting rust protection, follow up with a minimal coat of high-quality gun oil—one formulated specifically for firearms. This critical step not only protects against oxidation but ensures mechanical reliability for the next use. Routine inspection and reapplication of purpose-designed lubricants, rather than relying on all-in-one household products, should always conclude the cleaning process.

Alternatives to WD-40: What the Experts Recommend

Expert Consensus: Specialized gun cleaning and lubrication products exist because research and field experience demonstrate their superior ability to dissolve stubborn fouling and prevent corrosion. Unlike WD-40, modern formulations of CLP (Cleaner, Lubricant, Protectant) and synthetic gun oils resist breakdown at extreme temperatures and do not leave sticky residues.

Peer-reviewed occupational safety research and comparative studies have shown that products like Break-Free CLP, Slip 2000, and non-petroleum-based solvents outperform WD-40 in removing carbon and metallic fouling, reducing wear, and extending service intervals. While these dedicated solutions may involve greater up-front cost and the need for multiple steps (cleaning, lubricating, protecting), their targeted action ultimately ensures greater reliability and safety—an outcome every responsible firearm owner should prioritize.

Best Practices and Safety Tips for Gun Maintenance

Crucial Safety Insight: Many instances of firearm damage that come across my bench—ranging from corroded bores to jammed mechanisms—have root causes in preventable maintenance errors. Established safety principles such as always double-checking unloaded status, following a dedicated cleaning schedule, and using only proven gun maintenance supplies should be non-negotiable habits.

Effective maintenance is built on three pillars: comprehensive cleaning (to remove firing residue and old lubricant), proper lubrication (using the right amount and product for the job), and secure storage. When lubricating, selecting the right solvent and lube—and applying sparingly—is essential to avoid the common trap of over-lubrication, which results in trapping grit and powder particles.

Safe storage—including secure, unloaded placement and the possible use of a dehumidifier or silica desiccants—significantly minimizes the risk of accidental discharge, theft, or corrosion (see evidence-based guidelines). Following these best practices, rather than chasing “miracle” products, guarantees not only firearm performance but also your personal safety and peace of mind.

FAQs: WD-40 for Gun Cleaning

Is WD-40 safe to use on firearms?

What are the benefits of using WD-40 for gun cleaning?

Can using WD-40 damage my firearm?

How should I apply WD-40 when cleaning my gun?

Is there a better alternative to WD-40 for gun maintenance?

Conclusion: My Final Take on WD-40 and Gun Care

Final Assessment: No single product—including WD-40—can replace consistent, informed, and careful firearm maintenance. Years of hands-on experience and research confirm that WD-40 serves a limited, tactical purpose in gun care—mainly as an emergency field solution or brief rust preventative. For ongoing reliability and longevity, expert guidance and specialized cleaning products are essential. The key to effective firearm maintenance lies in understanding both your tools and your cleaning supplies, critically evaluating when and where each is appropriate. Safe, reliable gun care will always be grounded in knowledge, vigilance, and a willingness to adapt best practices as new evidence emerges.