“`html

Sleeving a firing pin enhances your rifle’s performance and longevity. It’s a subtle yet powerful modification that many shooters overlook, but shouldn’t. During my years as a firearms instructor, I’ve guided countless enthusiasts who, like me, realized that a well-sleeved firing pin can be the difference between a smooth shot and a frustrating misfire. What exactly is sleeving? It’s meticulously refining the fit and function of your rifle’s firing pin to ensure reliable ignition every time you squeeze the trigger. I’ve worked alongside seasoned gunsmiths and spent hours in the workshop myself to uncover the secrets we’re ready to share. Why haven’t you heard more about this? It’s a specialty topic often reserved for advanced tinkerers and those deeply entrenched in gun culture. Until now. Let’s dive in and demystify what sleeving the firing pin in your rifle truly involves.

“`

What is Sleeving?

In my experience, understanding terms like ‘sleeving’ is essential for effective communication among gunsmiths and hobbyists alike. It serves as both a bridge and a barrier: a bridge in how it allows us to refine and solve specific problems, and a barrier if misunderstood, marring both performance and safety. What exactly does ‘sleeving’ mean in the context of firearms? Well, this is where things get technical yet fascinating.

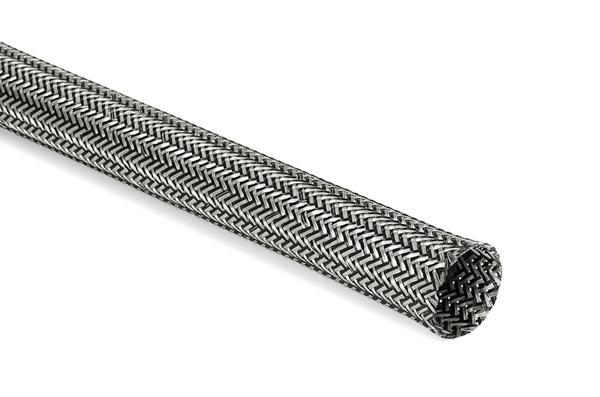

To put it simply, ‘sleeving’ involves inserting a sleeve—usually made of durable metal—into a part of the rifle, such as the firing pin channel, to improve or restore its functionality. It’s something I’ve done countless times in my career, each time appreciating more the subtleties and precision required. A common reason for sleeving a firing pin is to reduce excessive play or to correct wear that could affect the firing mechanism’s reliability. In essence, sleeving redefines the operating conditions of a weapon, ensuring that it acts not only with greater precision but also with heightened safety.

Delving into the art of firearms and their maintenance is more than a technical endeavor; it’s a journey of passion. Mastering techniques like sleeving requires patience, knowledge, and a steady hand—each rifle whispering its unique requirements, asking for just the right touch. As you continue through this article, we’ll uncover why sleeving is not just a repair, but a crucial step in maintaining the soul of your rifle.

Why is Sleeving Important?

Having spent years perfecting my skills in competitive shooting, I’ve learned that the devil truly is in the details. Every component, no matter how small, can influence performance. In fact, my keen appreciation for precision has taught me that sleeving the firing pin is vital for maintaining rifle reliability and accuracy. You might ask, “What are the unseen ramifications of neglecting sleeving on your rifle?” Here lies the crux of why sleeving is not just a recommendation but a crucial step for those serious about firearm maintenance.

Neglecting this seemingly minute task can lead to misfires, inconsistent firing pin strikes, and even damage to the bolt face over time. These issues are not merely inconveniences; they can be the difference between hitting your target and falling short. From firsthand experience, I’ve seen skilled marksmen falter due to overlooking such fundamental maintenance. It’s not just about preserving your rifle’s longevity but optimizing your shooting precision. When you take the time to sleeve the firing pin, you’re essentially ensuring the firearm’s harmony and efficiency.

Such attention to detail maximizes shooting performance and minimizes potential malfunctions. The importance of this process cannot be overstated, especially for those who compete or rely on their rifles for critical tasks. Viewed through the lens of my experiences, sleeving goes from an option to an essential practice that serious shooters cannot afford to overlook.

Who Needs to Know About Sleeving?

Are you a gunsmith, enthusiast, or just curious about your rifle’s mechanics? There’s a lot more to sleeving the firing pin than meets the eye, and understanding it can make a critical difference. In my years of working with firearms, I’ve come to realize the dedication it takes to maintain and enhance these powerful tools effectively. Even if you’re just stepping into this world, knowing who needs to be informed about sleeving will help you tremendously.

If you’re handling rifles—whether as a professional gunsmith or someone who enjoys tinkering in your garage—this knowledge forms the backbone of conservation and performance enhancement. As I’ve discovered throughout my journey, a precise comprehension of sleeving can save you not only time but also money in preventing premature wear and tear. Moreover, for those purely curious about the inner workings of rifles, understanding these intricacies can satisfy that inquisitive spirit while providing invaluable know-how. Why keep it a mystery when exploring this realm can be both rewarding and eye-opening? Understanding sleeving is essential, and it may just be the key to unlocking the full potential of your firearm.

When to Consider Sleeving?

I’ve often seen rifle owners wait until it’s too late – recognizing the signs early can potentially save you from costly repairs. As I peer into the intricacies of firearms, one question repeatedly arises: At what point should you seriously think about sleeving the firing pin?? This question beckons anyone passionate about their rifle’s longevity, performance, and safety. From my years in the field, I’ve learned that timing is essential. You need to consider sleeving when subtle signs of wear start to whisper through your rifle’s actions: misfires, primer sensitivity issues, or visible erosion around the pinhole.

Too often, gun owners overlook these initial symptoms. I recall a time when a client brought in a rifle that misfired unexpectedly. Upon inspection, I discovered the culprit—a badly worn firing pin that should have been sleeved months earlier. His case wasn’t unique, but it served as a stark reminder of the importance of vigilance. Preventative action can make a world of difference. It’s crucial to tune in to what your rifle is telling you, long before the problems escalate.

Moreover, if you frequently reload your ammunition or use a particular rifle for high-volume sessions, it’s critical to preemptively consider a sleeving procedure. This isn’t just about solving issues—it’s about maintaining peak performance and prolonging your firearm’s life. By addressing these signs proactively, not only do you preserve your rifle’s integrity, but you gain confidence in every shot you take.

How to Sleeving a Firing Pin

Gather Necessary Tools and Materials

What tools do you really need to successfully sleeve a firing pin? As someone who has spent countless hours at the gunsmith bench, I can’t stress enough how crucial proper tool preparation is. Without the right tools and materials, attempting to sleeve a firing pin assembly is like setting out to sea without a compass. To begin, you’ll need a bushing set that’s specifically designed for your rifle’s firing pin, a good set of micrometers, a lathe, and cleaning materials. These aren’t just items on a checklist; each plays an integral role in ensuring precision and avoiding damage.

I’ve seen too many DIY enthusiasts falter because a critical tool was missing—or worse, because they tried to make do without the correct bushing. Preparation goes beyond mere procurement; it’s about understanding the nuanced tasks each tool performs, paving the way for a successful firing pin assembly sleeve. The road to precision, my colleagues, begins with meticulous preparation.

Step-by-Step Sleeving Process

Having performed this procedure numerous times, I’ve developed a step-by-step guide that ensures you won’t miss any crucial steps. Can you confidently execute the sleeving process without missing critical steps? With my expertise in gunsmithing terminology, maintenance, and repair, I’ll guide you through this essential component of firing pin sleeving. This intricate task, a cornerstone in the ‘How to Sleeving a Firing Pin’ segment, demands precise attention to every detail to guarantee your rifle’s performance and reliability.

First, it’s vital to secure your workspace, ensuring all tools and materials are within easy reach. Begin by removing the bolt from your rifle and disassembling it to access the firing pin. Inspect the firing pin closely for any signs of wear or damage. This isn’t just routine maintenance—it’s a necessary step in ensuring your weapon operates safely and effectively. Using my methodical approach, you’ll replace the worn sleeve with precision, maintaining the integrity essential in firing pin function.

Throughout this process, pay careful attention to the alignment and fit of the sleeve. This isn’t merely a repair; it’s a deep dive into rifle mechanics—ensuring that each reassembled component operates with impeccable harmony. As we transition into the next segment, take a moment to appreciate how even minor adjustments can significantly enhance your rifle’s performance, setting the stage for avoiding common mistakes. Remember, mastery in gunsmithing is as much about precision as it is about understanding the nuanced dance of its elements.

Common Mistakes to Avoid

What common pitfalls can jeopardize your sleeving project? Throughout my career, I’ve learned that mistakes in the sleeving process often turn a straightforward project into a major headache. Many enthusiasts dive into gun repairs with enthusiasm but overlook crucial details. First, improper measurements of the firing pin and sleeve dimensions can lead to ill-fitting components. Always double-check these measurements; it’s better to measure twice and cut once. Misalignment during installation is another common mistake. Ensuring everything lines up correctly is paramount for safety and function. I’ve seen too many sleeving projects jeopardized by rushed work, leading to malfunctions or even damage. Patience is key—don’t succumb to the temptation of jumping steps to save time. Poor equipment choices can also impede progress and results. Investing in quality tools not only facilitiates this procedure but also enhances the overall efficacy of your work. Avoiding these errors ensures a smoother process and reliable performance.

FAQs

Why is sleeving the firing pin important?

Sleeving the firing pin can enhance the reliability of your rifle by ensuring more consistent primer strikes, reducing the chance of misfires.

What are the benefits of sleeving the firing pin?

The benefits include improved accuracy, enhanced primer ignition, and increased safety by minimizing the risk of the firing pin striking off-center.

What should I consider before sleeving my firing pin?

Before proceeding, consider the type of rifle, the intended use, and consult a gunsmith if unsure. Ensure that modifications comply with local laws and regulations.

Are there any risks associated with sleeving the firing pin?

If not done correctly, sleeving can lead to malfunction, increased wear, or damage to the firearm. Expert guidance or professional intervention is recommended.

Conclusion

Are you now prepared to tackle sleeving your firing pin with confidence? As someone who’s spent years in the gunsmithing trenches, I know the art and precision required for sleeving a firing pin in your rifle mechanism. This journey through the essential “what,” “why,” “who,” “when,” and “how” of the process has aimed to equip you with the right tools and methods. Understanding the significance of sleeving not only enhances your rifle’s performance but ensures your safety and satisfaction during each shot.

By identifying common mistakes and avoiding them, you can sidestep potential pitfalls. Remember, proper preparation is crucial. My goal has always been to empower shooters to take control, and I hope this guide has sparked the confidence you need. After guiding many through the intricacies of gunsmithing, I’m excited to see more enthusiasts embrace this knowledge. Take this newfound expertise and breathe new life into your rifle with precision and assurance.